ESC - Electronic speed controller - Part 1

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

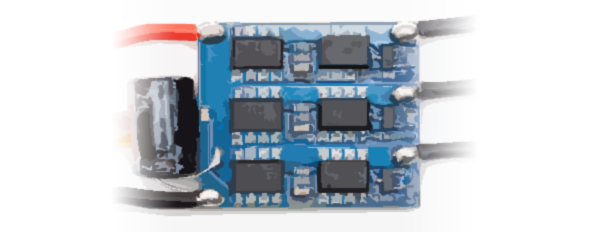

Whenever we have a system with a microcontroller acting on motors, we'll definitely find voltage and current problems. The micro processors typically work at a voltage of 3.3 or 5 volts and use very low power. Instead motors are beasts whose main food is current. In a project that uses motors we can consume more than 20A and that amount of current won't be given by any microcontroller. Therefore we need to separate the high amp 12V part of our circuit from the low 5V part. When i say motors I refer to triple phased brushless motors. By having three-phase motors things get complicated compared with a simple DC motor. We have to power 3 inputs to the motor in a very precise sequence. To generate that sequence of high or low state of the motor inputs we will use an ESC (electronic speed control).

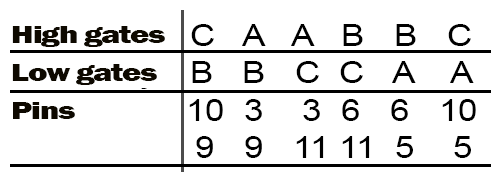

We can see in the animation above that we have to switch 3 inputs H1, H2 and H3 in a certain sequence. We will call the 3 inputs, input A, B and C. The sequence we need to create is as follows:

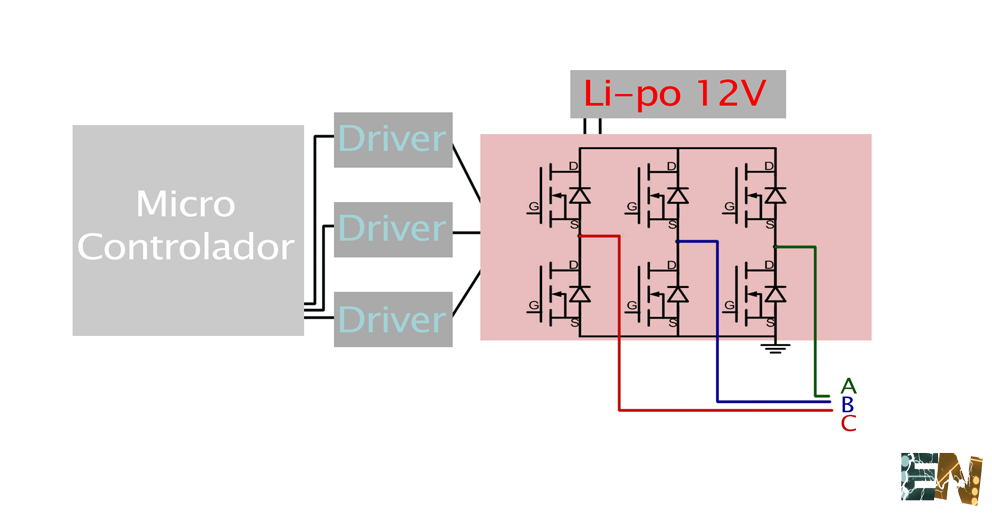

Where the high gates referes to the transistors connected to Vdd and low gate to the transistors connected to GND in our three-phase bridge that we can see below. The pins represent connections to the microcontroller.

Schematic three-phase bridge!

A little bit of extra info

We observe the general schematic of an electronic speed controller and divide it into three parts. First of all we need a microcontroller that will make the micro-process part. The microcontroller processes the data and decide which signal has to be send to the next part, the drivers. The function of these drivers is to apply the necessary voltage at the mosfets transistors gates of the third part called three-phase bridge and open or close the flow of current through these transistors. Finally, the third section bears the name of three-phase bridge. We have to power a three-phase motor following a certain sequence and flow the current through the motor windings. Opening and closing 6 transistors in a very precise way we could achieve the desired sequence in order to rotate the motor.

As already mentioned the schematic is very general. To synchronize the rotation speed of the motor with our generated sequence at all time we need to control the motor position and compare it with the desired position. For that we measure the EMF or electromagnetic field created by the rotation of the motor, like dynamo magnets create a certain electromagnetic force in the motor windings. By measureing the voltage drop in the motor terminals we can make a fine micro-process and know the position of the motor and synchronize each turn.

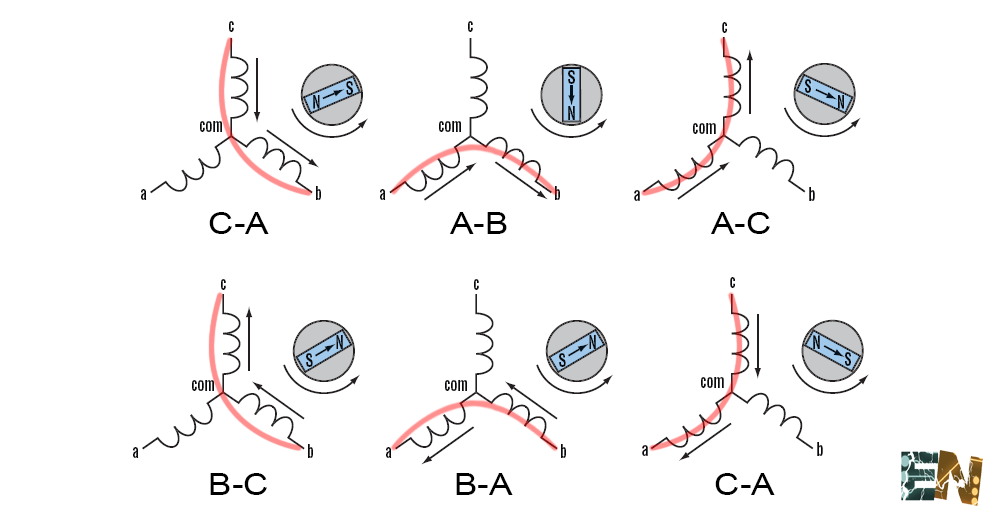

6 steps of the motor spin sequence:

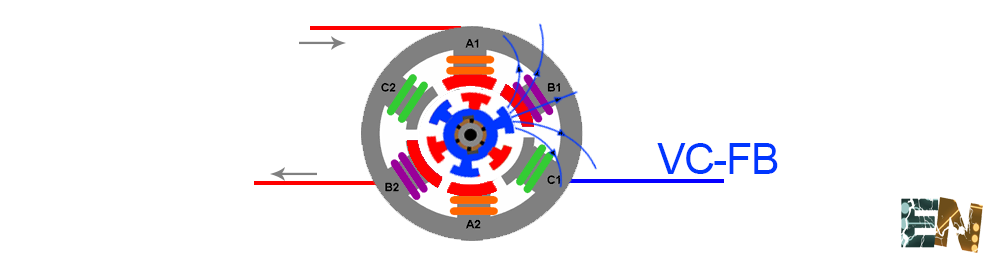

To understand better the inner function of a three-phase brushless motor we look at the figure above. We know that the motor has a multiple of 3 number of coils. The coils are distributed equidistantly around The perimeter of the motor. In this way between each coil there will be 360 degrees divided by the number of coils. In our case the engine is 12 coils, 4 coils for each of the 3 inputs. In the above figure those are represented by only one coil for each input. The moving part of the motor can be external or internal shaft , in this case is external. Around the movable part we need to place some strong magnets in the same way as the 12 coils, equally spaced. We know that applying a current flow through the coils, a magnetic field is created depending of the current flow direction. Alternating the current flow direction through the coils, we alternate the polarity of the electromagnetic field created in souch a way that we'll have opposite poles between the coils and magnets in certain points of time. Looking at the figure we can see that we start switching the upper "C" gate and the lower "A" gate. In this way we make current flow from C to A, creating a magnetic field through the two coils. That created field is opposite to the magnets field and that creates a push force which move forward the interval axis (360/12 degrees). Just at the moment when the coils pass through one each other middle, the next magnet have to switch to the next state so we have to make current flow from A to B and so forth creating an infinite loop that repeats every 6 states.

How to detect BEMF and sincronise our sequence:

We know that a magnet creates a magnetic field around it. Once you put a coil in front of him, the movement change the field flow through the coil creating a current flow throug the windings. As more field flows through the coil, higher current intensity passes through the winding and a higher tension could fall on the terminals. Let's look at the next BEMF detection example:

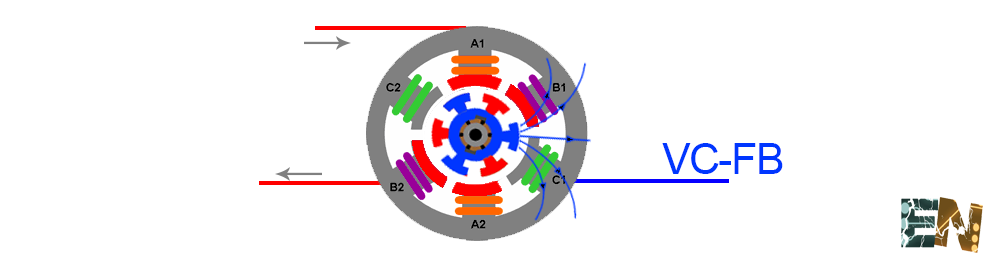

We observe in the above figure that the upper gate of the A output and the lower gate of the B are activated. That creates a curent flow from A to B coils in the direction of thee grey arrows. This current flow creates a equal magnetic field in bowth A and B coils. That magnetic field will push the oposite magnetic field of the exterior magnets rotating the motor. In this example we call the red color of the magnets south polarized and the blue ones north polarized. We obserbe blue arrows getting out of the blue magnet. Let's look at the C coil for now. Those field lines are not crossing the C coil yet. We can see that almost all the field lines are out of the coil but in the next figure, a few moments after we can see that there are a few lines crossing the coil. In this way the created current flow it is afected by the rotation of the motor. This gives us a voltage change VC-FB which we can measure with our microcontroller ADC. As the field lines are geting more perpendicular to the coil, the current flow is higher each time and so it's the voltage drop.

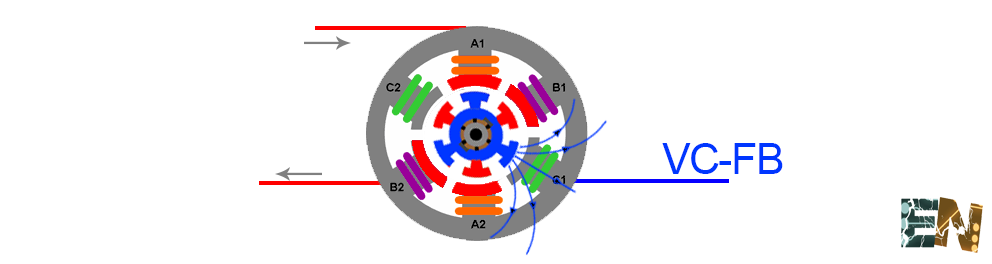

In the next figure we observe that the field lines are totally crossing the C coil. This means that the field flow is maximum and so is the current flow in the C coil. This is the exact moment when we need to change to the next step of our sequence. If we are able to detect this exact moment with our microcontroller we could jump to the next part of our sequence in the right moment. AS we could see, we have a voltage drop in non-activated coil which depends of the motor movement. We can measure that voltage drop using our ADC and compare it with the mean of all 3 coils voltage. When we detect that maximum voltage we could make the sequence change.

Let's start

We already know what we have to do. Mount the three-phase bridge, connect a microcontroller and read the outputs of BEMF of the motor and create a switch sequence depending on that BEMF read. First of all we create a schematic in Design Spark program. You can use any PCB design program. To make the schematic import all specified components. Make the connections and create the PCB.

About me

About me  History

History  Let's learn

Let's learn  Contact us

Contact us  Arduino tutorials

Arduino tutorials Circuits tutorials

Circuits tutorials  Robotics tutorials

Robotics tutorials Q&A

Q&A Blog

Blog  Arduino

Arduino  Circuits

Circuits Robotics

Robotics  Modules

Modules  Gadgets

Gadgets  Printers

Printers  Materials

Materials  3D objects

3D objects  3D edit

3D edit  Donate

Donate  Reviews

Reviews  Advertising

Advertising